Modern Construction: Harnessing Innovation and Sustainability for the Future

As modern society evolves rapidly, so too must construction adapt to meet its demands. Through innovative and eco-friendly practices, new techniques are revolutionizing how building projects are approached. This article will explore several key aspects that are shaping contemporary construction.

Firstly, we delve into innovative techniques that have transformed traditional methods in favour of more efficient and cost-effective solutions. Next, sustainable practices take centre stage as eco-friendly approaches become increasingly important for both clients and builders alike.

Moving forward, technology plays a crucial role in streamlining project management processes – from planning to execution – ensuring smoother operations across all stages of development. Lastly, addressing labour shortages remains a pressing concern within the industry; automation and robotics offer promising alternatives to bridge this gap while enhancing overall productivity.

Join us as we examine these pivotal factors contributing to the advancement of modern construction practices.

Over recent years, the construction industry has witnessed dramatic transformation due to advances in technology and innovative building techniques. This shift towards modern construction methods has not only improved efficiency but also contributed to sustainable development and enhanced safety standards on job sites. In this article, we will explore some of the key aspects that define modern construction practices, including Building Information Modeling (BIM), prefabrication and modularization, green building technologies, as well as smart buildings.

Building Information Modeling (BIM) is at the forefront of modern construction practices. BIM is a digital representation of a building’s physical and functional characteristics throughout its life cycle – from design to demolition. It enables architects, engineers, contractors and owners to collaborate effectively using shared information about every aspect of a project. The use of BIM reduces errors during design phases by identifying potential issues before they become costly problems on site; it also streamlines communication between stakeholders involved in different stages of the project lifecycle. Furthermore, BIM helps optimize resource allocation through accurate quantity takeoffs for materials procurement or labour scheduling purposes while minimizing waste generation due to over-ordering supplies or inefficient work processes.

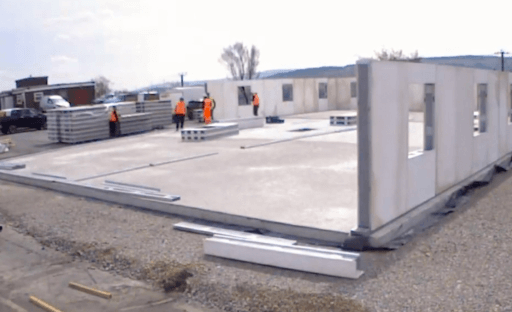

Prefabrication and modularization are other essential components that have revolutionized traditional approaches within the industry by offering numerous benefits such as reduced costs associated with labor-intensive tasks performed onsite; shorter schedules resulting from parallel activities being carried out offsite simultaneously alongside onsite works; increased quality control measures implemented at factory level rather than relying solely upon inspections conducted post-installation stage which may lead delays rectifying defects discovered later down line if left unchecked initially during production phase itself prior shipment final destination where assembly takes place ultimately saving both time money overall end-users clients alike who can now enjoy faster delivery times better value products services offered them market today thanks these innovations brought forth current era contemporary architecture engineering worldwide global scale never seen before until now present day age civilization mankind human history known existence planet earth universe cosmos reality space-time continuum dimension existence.

Innovative Techniques Revolutionizing the Construction Industry

The construction industry is undergoing a revolution, with innovative techniques being used to build faster and more efficiently than ever before. From 3D printing to prefabrication, these modern methods are transforming the way we construct buildings and infrastructure.

3D printing has been around for some time now but its application in the construction industry is relatively new. This technology allows architects and engineers to create complex structures quickly using computer-aided design (CAD) software. It can also be used for rapid prototyping of components or entire buildings, allowing designers to test their ideas before committing them to production.

Prefabrication is another technique that’s gaining traction in the construction world as it enables builders to assemble parts of a structure offsite and then transport them onto the site when needed – reducing labour costs and speeding up project timelines significantly. Prefabricated walls, ceilings, floors and other components can be produced at factories and then shipped directly onto building sites where they’re ready for assembly without any further work required onsite by workers or machines – saving both time and money on projects large or small.

Robotics are also making an impact in this sector as robots can carry out tasks such as welding with greater accuracy than humans while working much faster too – meaning fewer mistakes during fabrication processes which ultimately leads to better quality results overall when compared with manual labour alone. Additionally, robotic arms have been developed that allow materials like concrete blocks, bricks, tiles etc. To be placed accurately into position without human intervention – again leading towards higher levels of efficiency within the industry.

Finally, drones have become increasingly popular amongst builders due to their ability to capture aerial images from above which helps surveyors map out terrain more accurately whilst providing valuable insights into potential hazards such as power lines or underground utilities prior to commencing works onsite.

All these technologies combined together are revolutionizing how we approach constructing our built environment today – enabling us complete projects quicker than ever before whilst still maintaining high standards throughout each stage of development along the way!

Sustainable Practices for Eco-friendly Modern Construction

Sustainable practices are becoming increasingly important in modern construction. With the rise of climate change, it is essential to ensure that our buildings and infrastructure are designed with sustainability in mind. This means using materials that have a lower environmental impact, reducing energy consumption during construction and operation, and minimizing waste production.

One way to achieve this is through the use of renewable resources such as bamboo or recycled steel for building components. These materials can be used in place of traditional timber or concrete products which require more energy-intensive processing methods and generate more emissions during their manufacture. Additionally, they offer greater durability than conventional materials while still being eco-friendly – making them an ideal choice for sustainable construction projects.

Another key element of modern sustainable construction is efficient insulation systems which reduce heat loss from buildings while also helping to keep interior temperatures comfortable throughout the year without relying on excessive heating or cooling systems powered by fossil fuels. The use of high-performance glazing can also help reduce solar gain while allowing natural light into a building’s interior spaces – further reducing its reliance on artificial lighting sources powered by electricity generated from nonrenewable sources such as coal or gas power plants.

Finally, it’s important to consider how water will be managed within a building when designing for sustainability; rainwater harvesting systems can provide an alternative source of water supply for irrigation purposes while greywater recycling helps minimize wastewater generation from sinks and showers inside the structure itself. By taking these steps towards creating eco-friendly modern constructions we can help create healthier living environments now and into the future!

The Role of Technology in Streamlining Project Management

The modern construction industry is increasingly reliant on technology to streamline project management. Technology has revolutionized the way projects are managed, allowing for greater efficiency and accuracy in all aspects of the process. From planning and scheduling to budgeting and resource allocation, technology can help ensure that projects are completed on time and within budget.

One of the most important benefits of using technology in project management is improved communication between teams. By utilizing digital tools such as video conferencing, instant messaging, or even virtual reality simulations, teams can collaborate more effectively from any location around the world. This allows for faster decision-making processes while also providing a better understanding of each team member’s role in completing a task or achieving an objective.

Technology also provides access to real-time data which enables managers to make informed decisions quickly based on current trends or conditions at any given moment during a project’s lifecycle. With this information readily available at their fingertips, managers have greater control over budgets and resources while ensuring that tasks remain on track throughout every stage of development – from concept through completion – resulting in successful outcomes for both clients and contractors alike.

Finally, automation technologies such as robotic process automation (RPA) enable businesses to automate tedious manual tasks associated with managing large-scale projects; freeing up valuable time so that employees can focus their efforts elsewhere where they may be more productive or creative instead – ultimately improving overall performance across all departments involved with construction operations.

In conclusion, it is clear that leveraging technological solutions offers many advantages when it comes to streamlining project management within modern construction organizations. Not only does it improve communication between teams, and provide access to real-time data, but also helps reduce costs by automating mundane tasks; thus enabling businesses to achieve higher levels of success than ever before.

Addressing Labor Shortages with Automation and Robotics

As the construction industry continues to grow, labour shortages are becoming increasingly common. To address this challenge, many companies are turning to automation and robotics as a way of reducing their reliance on manual labour. Automation and robotics can help reduce costs associated with hiring workers, while also increasing productivity levels and improving safety standards in the workplace.

Robotics have been used in construction for decades now, but recent advances in technology have made them even more useful for addressing labour shortages. Robotics can be programmed to perform repetitive tasks quickly and accurately without needing human intervention or supervision. This not only reduces costs associated with manual labour but also increases efficiency by allowing robots to complete tasks faster than humans could ever hope to achieve on their own. Additionally, robotic systems can be designed specifically for certain types of work that require precision or accuracy which may otherwise prove difficult or dangerous for human workers due to fatigue or other factors such as hazardous working conditions.

Automation is another tool that has become increasingly popular among modern construction companies looking to address their workforce needs efficiently and cost-effectively. Automated systems allow machines such as cranes, bulldozers, excavators etc., to operate independently from human control using preprogrammed instructions set up by engineers who understand how these machines should function under different circumstances within a given environment. This eliminates the need for direct supervision from an operator while still ensuring that all safety protocols are followed at all times during operation – something which is essential when it comes to preventing accidents on site due to negligence or lack of experience amongst operators.

Overall, automation and robotics offer an effective solution when it comes to addressing labour shortages within the modern construction industry.